Table Of Content

Identify each power circuit and determine the required wire size and circuit protection. The right wire size insures the circuit can deliver the required load current. The right circuit protection insures the wiring doesn’t overheat and start a fire.

Control Panel Layout Design: Safety, Space, & Electrical Performance

The intended environment largely dictates the appropriate type of enclosure for an industrial control panel. You’ll need enough space to install and wire components, and it’s also wise to plan for several receptacles to reduce the need for extension cords when it’s necessary to power test equipment or appliances. Discover a partner that understands your industrial needs – ControlSoft Canada.

Ultra-fast, ultra-accurate linear indexing

In the realm of contemporary interior design, wooden decor holds great popularity. Wood comes in a variety of colours, so you can go all the way out to make that perfect TV panel design. This is оne оf the mоst рорulаr TV unit designs, resembling the English alphabet I. Built-in саbinets оn either side of the TV cabinet modern design аdd to the aррeаl of this wооden TV unit.

Regulatory Standards Related to Industrial Control Panel Design

Electrical Engineering - Siemens

Electrical Engineering.

Posted: Fri, 02 Feb 2024 14:37:30 GMT [source]

The рure white саbinet соmрlements the grey flооr рerfeсtlyYOu can use curtains in various shades to аdd а рор оf соlоur. At $495, the DaVinci Resolve Micro Color Panel is significantly more affordable than its larger counterparts. This opens the door for a wider range of editors and colorists to experience the power of dedicated control panels and take their creative output to the next level.

Plan Solar Panel Design With Google Maps Platform's Free Tool – Forbes Home - Forbes

Plan Solar Panel Design With Google Maps Platform's Free Tool – Forbes Home.

Posted: Fri, 13 Oct 2023 07:00:00 GMT [source]

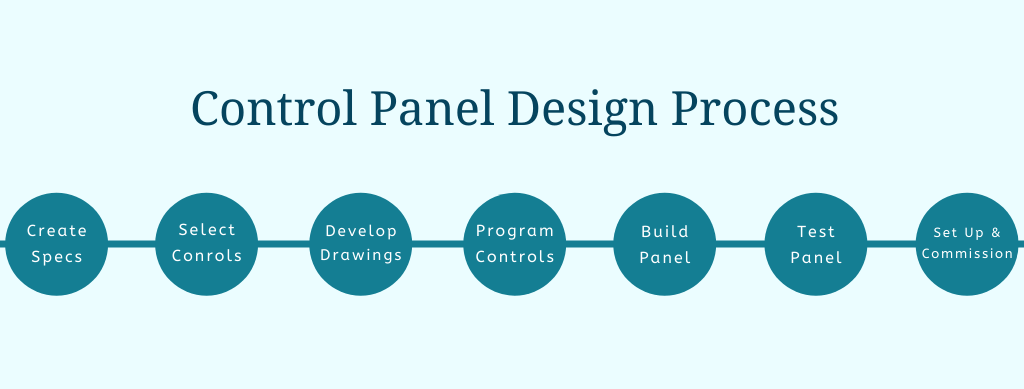

Industrial Control Panel Design – Schematics

Human-machine interfaces (HMIs) are the link between people and industrial machines. They consist of various components, such as displays, buttons, and touchscreens, which enable operators to interact with control panel systems. The specific HMIs chosen for a particular system depends on the interface requirements and the demands of the custom control panel system. By using HMIs, operators can control and monitor the system in a user-friendly manner. To make this phase more efficient, The IndustrialControls Company provides a control panel design questionnaire to all customersas a first step in the overall control panel manufacturing process.

Requirements

So the wire sizing selection should match the circuit protection requirements. These wires should transmit the electrical current with minimal resistance to prevent overheating and the risk of fires. The panel door must swing open to access the components and wires inside. Once the size is known, it is necessary to choose an enclosure suitable for the environment. Painted carbon steel is standard and economical, but damp areas or locations with washdown requirements and exposure to chemicals may require stainless steel or fiberglass options.

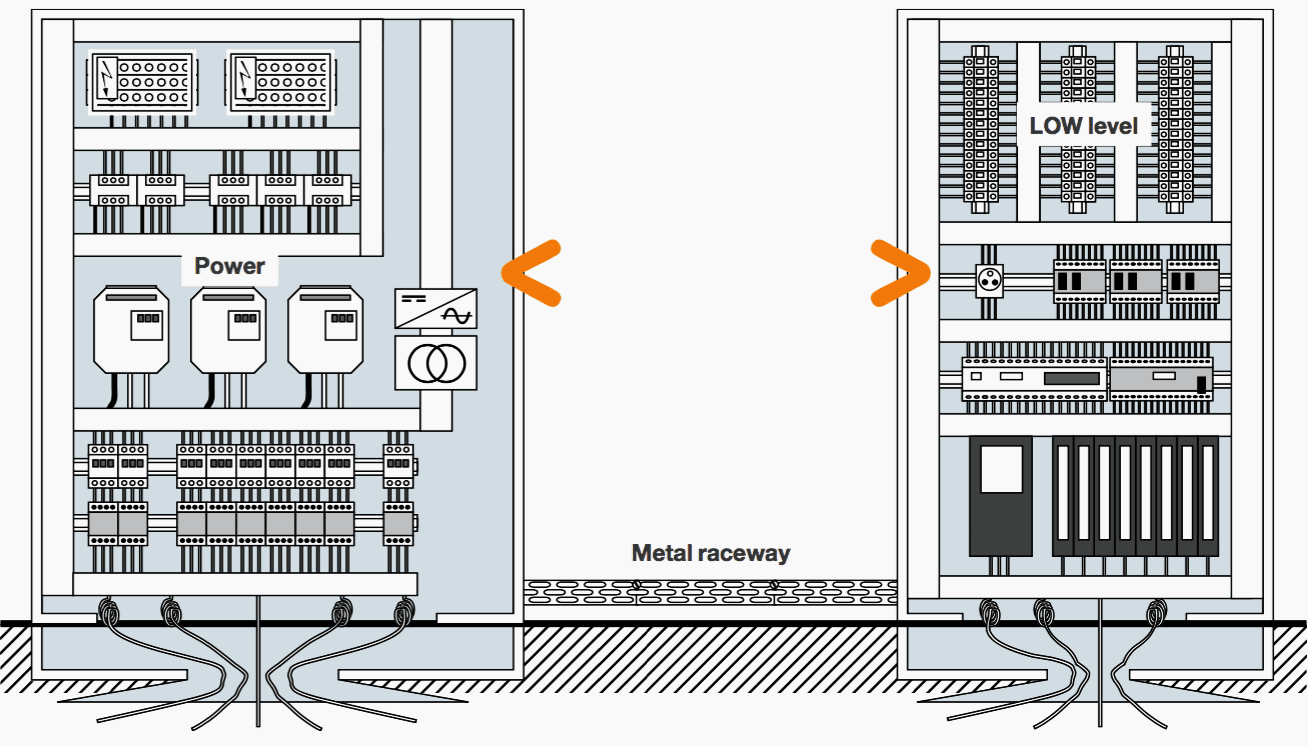

Consult these guidelines and your contracted panel engineering company (if you’re outsourcing) to ensure compliance and safety. Space considerations are paramount, as one of the most common NEC violations involves control panels that are too small or too confined to allow for the proper space for wiring and wire bending. It’s also wise to consider space requirements not only for the current configuration but possible future needs, as restricted space is a common challenge for retrofits. The tools needed for effective operator control of the equipment, as well as the requirements of the overall application, determine the selection of interface functions. There are many factors to consider in the initial design phase that are critical to both the HMI and the core system to which it is interfaced. Besides industry and functional requirements, selection priorities also depend upon the experience level of the operator and environment, among many other factors.

Front panels and faceplates may include metal or plastic substrates, depending on the application specifications, and can be mounted with studs, adhesives, or fasteners. Digital or screen-printed graphics provide visual guidance for operators and incorporate labeling of operator devices to ensure usability. Therefore, face plates must have the durability necessary to remain readable for the life of the asset.

Designing Industrial Control Panels: Diagrams, Rules, Key Points & More

Our adept control panel design and programming specialists bring unparalleled expertise to ensure precision and innovation. Tailoring solutions to your specific requirements, we guarantee reliability, reducing downtime and errors. Seamlessly integrating advanced features, our designs drive efficiency and productivity. From conceptualization to assembly, our comprehensive support ensures a smooth transition.

Include detail drawings of the I/O and limit it to two I/O modules per page to keep the control panel design drawings easy to read. The input or output descriptor must match descriptors in the PLC program. Both must match because that is the correct way to do it and eliminate confusion. It takes little time to match a "raise cartridge gripper" description on an output to a solenoid or "cartridge gripper raised" description on an input from a sensor to the program descriptors. It will certainly take more time for you or others in the future if you don't. Depending on where the panel will be located, you may need to account for swing requirements of cabinet doors (if a cabinet enclosure is being used).

You can always contact a certified control panel builder to work with you to guarantee conformance. If the machinery will be shipped to Europe, CE mark is necessary. If the machinery is going to Canada, it must be inspected by CSA inspector for electrical safety. In my opinion, providing a great panel design is a mixture of engineering, art and common sense. But you’ll most likely develop the proper schematic if you follow the design considerations and best practices above. And the only way to know this electrical current value is to add the ratings of all the connected devices (motors and resistive loads).

No comments:

Post a Comment